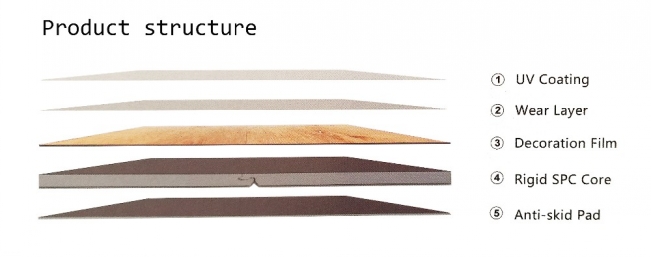

SPC floor has zero formaldehyde, mildew proof, moisture proof, fireproof, insect proof and simple installation.

SPC Foor Manufacturing Process:

Step 1:Material mixing:

Put the material into mixing machine. Hot mixing then cool mixing.

Step 2:Extruding

Put the material into Conical or parallel twin screw extruder. Heating and extruding→die→4 or 5 roller calender→Film laminating→wearing layer laminating→cooling→cutting→auto-stacker. All these procedures are automatically finished in the extrusion line.

Step 3:UV

UV coating

Step 4:Cutting, lock making and packing

Cutting→locking making→inspecting→packing

| No | Model number | SJSZ110/220 | SJSZ115/230 | SJSP136 |

| 1 | Double screw type | Conical | Conical | Parallel |

| 2 | Extruder motor | 185KW | 200KW | 160KW |

| 3 | Total power | 350KW | 380KW | 300KW |

| 4 | Rollers of Calender | Five rollers | Five rollers | Five rollers |

| 5 | Capacity | 1000-1300kg/h | 1600-1900kg/h | 1700-2100kg/h |

| 6 | ㎡/24h

(4mm thick floor as example) |

about 3000-3500 | about 4500-5500

|

about 5000-6000

|

SPC floor has a wide range of color patterns to choose from, suitable for indoor home improvement, hotels, hospitals, shopping malls and other public places.

Contact

Contact