Production process

Feeder→ Conical Twin-screw Extruder → Mould →Calibration Table → Haul-off → Cutter → Cutter → Stacker

(Note: Other Auxiliary Machine, such as crusher, mixer, etc. will be provided according to client’s requirements)

Machine Features

1, the equipment has the characteristics of mixing, plasticizing and dispersion effect is good. Due to the good dispersion of mixing and plasticizing, the filling amount is high (up to 70%-75%).

2, because the barrel and screw are made of special materials, the service life of the equipment is twice longer than other equipment.

| No. | Name of Equipments | QTY |

| 1 | Automatic Feeding Machine | 1set |

| 2 | SJSZ-65/132 Conical twin-screw Extrusion machine | 1set |

| 3 | ZK6000 Vacuum Calibrating Table | 1set |

| 4 | SLQG-1800 Haul-off and Cutting Machine | 1set |

| 5 | Auto-stacker | 1set |

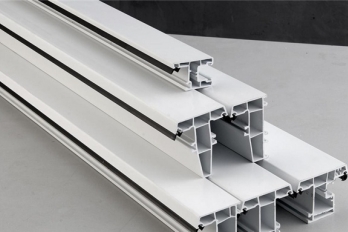

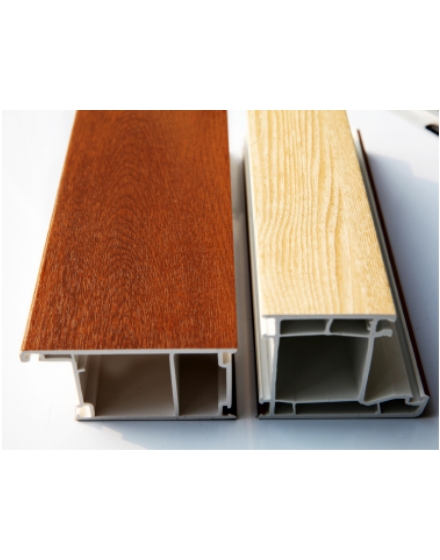

With different mould,machine can produce WPC and PVC products with different shapes, like window, door frame, decorative line, trunking and so on.

Contact

Contact