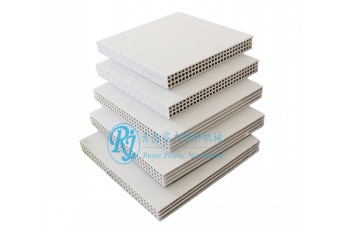

Advantages:

- Good water resistance. Even if it is completely immersed in water for many days, it will not deform and rot due to moisture.

- It is not compatible with cement, easy to demould after construction, and will not be deformed by cement adhesion.

- High construction efficiency and good quality. The surface of the building is smooth and flat, and don’t need secondary modification.

- Save production time and improved the construction efficiency.

- Light weight and convenient construction.

- Long life and recycled. The final PP hollow building template can still be crushed again, re-process into a new template, saving resources and meeting the requirements of “green industry”.

- Good insulation, which is conducive to shortening the construction period.

- The template can be sawed, planed, turned, drilled, nailed, and can be freely formed into any geometric shape to meet the needs of various shapes of building supports.

Parameter:

single-screw extruder, hydraulic screen changer, mould, calibration table, primary traction machine, cooling bracket, secondary traction machine, cross-cutting machine

Application scenarios:

The template can be sawed, planed, turned, drilled, nailed, and can be freely formed into any geometric shape to meet the needs of various shapes of building supports.

Contact

Contact