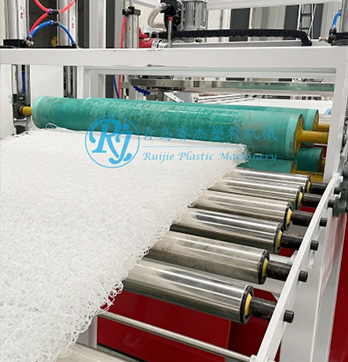

This production line uses a high-quality single-screw extruder as the main machine, adopts a PLC control system, is equipped with a hydraulic automatic screen changing system, a right-angle spinneret die, cooling water tank(assembled with a chiller),dehydration device,haul off unit,cutter and stacker.

| EXTRUDER MODEL | PRODUCT WIDTH | PRODUCT THICKNESS | MAIN MOTOR POWER | INSTALLED CAPACITY |

| SJ75/33 | 500 | 1-100mm | 45kw | 100kw |

| SJ120/33 | 2000 | 1-100mm | 132kw | 220kw |

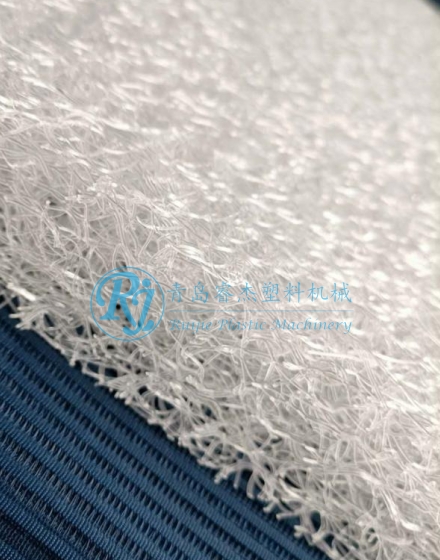

This production line is used to produce polymer air fiber mattresses, cushions, pillows and other series of air fiber products.

At present, the product is widely used in nursing homes, hospitals, etc. as nursing mattresses, dry and breathable, without bedsores, used in kindergarten and school dormitory mattresses, pet mats and home tatami mats, etc., completely washed, highly elastic and comfortable and gradually replace the traditional interior core material is popular among consumers.

Contact

Contact