What is POE?

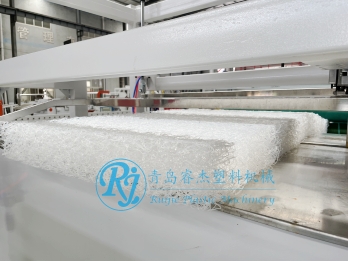

The polymer mattressl is made of POE as raw material. With the advanced technology, each filament is made into a hollow three-dimensional structure, and air-weaving technology is used for molding. The raw material is graded pure imported medical grade, which can directly contact with food (Passed TUV food grade inspection). This is an environmentally friendly and hygienic polymer material. It has the property of water permeability, adhesion, high elasticity, antibacterial, environmental protection, adhesion, durability, which other materials do not possess.

Features:

1. Moisture absorption and breathable

2. Comfirtable and spine protection

3. Mite-proofing and antimicrobial

4. Environmental

5. Sound off all night

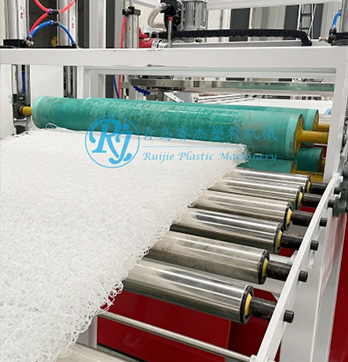

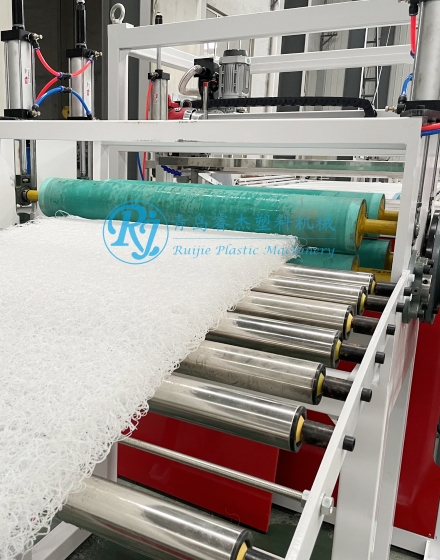

| No | Machine | Qty |

| 1 | SJ Single screw extrusion machine | 1 set |

| 2 | Screen changer | 1 set |

| 3 | Mould | 1 set |

| 4 | Spinneret plate | 1 set |

| 5 | Forming water tank | 1 set |

| 6 | Dehydration Device | 1 set |

| 7 | Traction machine | 1 set |

| 8 | Cutting machine | 1 set |

Pillow Core, Mattress core, Back cushion core, Throw pillow core.

Contact

Contact