Advantages:

- Selecting the superior quality of raw material.

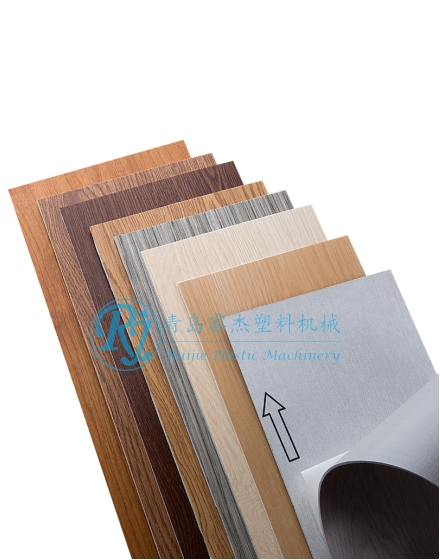

- A wide range of applications.

- Simple and practical design, easy to install.

- Offering an affordable price but excellent quality.

- Various choices of color and size.

- High performance in waterproof, anti-slip, fire resistance and wear resistance.

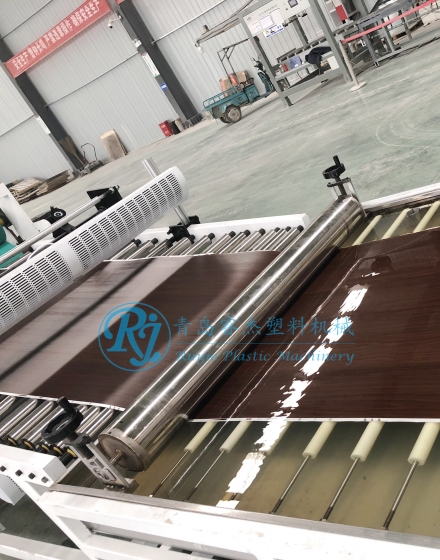

Parameter:

| LVT flooring machine line consist of | ||

| No | Item name | Content |

| 1 | Conical twin screw extruder | SJSZ92/188 or SJSZ80/156 |

| 2 | Mold(T-Die) | 1050mm |

| 3 | Calender | 4 rollers |

| 4 | Water cooling bracket | |

| 5 | Haul-off machine | |

| 6 | Cutter | |

| 7 | Automatic stacker | |

| 8 | Electrical control | ABB inverter Siemens motorSiemens contactorSiemens touch screen |

| Auxiliary machines | ||

| 1 | Mixer | SRL_Z500/1000 |

| 2 | Crusher | SWP680 |

| 3 | Grinder | SMP600 |

| 4 | UV coating machine | |

| 5 | Punching machine | |

| 6 | Adhesive machine | |

Application scenarios:

LVT floor can used in Apartment, hotel, school, hospital, office, shopping mall. ect

Contact

Contact