Through 「Corona Treater」, using high-voltage and high-frequency waves, the electric shock molecules are ejected from the air nozzle, and the molecular structure is destroyed by the electric shock and penetration into the surface of the printed body, so that the surface of the printed body increases the adhesion ability, and can be coated or printing.

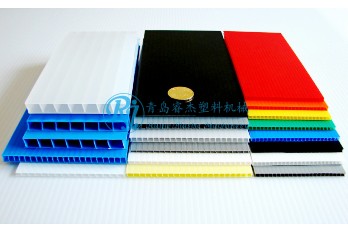

The feature of PP hollow profile has non-toxic, 100% recycled, light weight, low temperature resistance, waterproof and moisture proof, corrosion resistance, impact resistance, energy absorption, noise blocking effect.

| Item | Description | |

| Control | Touch panel, Automatic control system | |

| Feeding | Continuous Auto Weighing System, Gravimetric blending control system, Master-Batch doser, Dehumidifying dryer |

|

| Material | Virgin PC / PC+UV | PP |

| Extruder | Ø100、Ø120 | Ø150、Ø180 |

| Line Speed | 2-6 m/min | 2-18 m/min |

| Thickness | 4.0-20.0mm | 2.5-20.0mm |

| Area Weight | 950-2600g/m2 | 1100-3000g/m2 |

| Sheet Width | 1000-2400mm | 1000-3000mm |

| Output | 400kg/h | 800kg/h |

| Layer | ABA、BAB、AB | ABA、BAB、AB |

| Note | Customized is available for high capacity | |

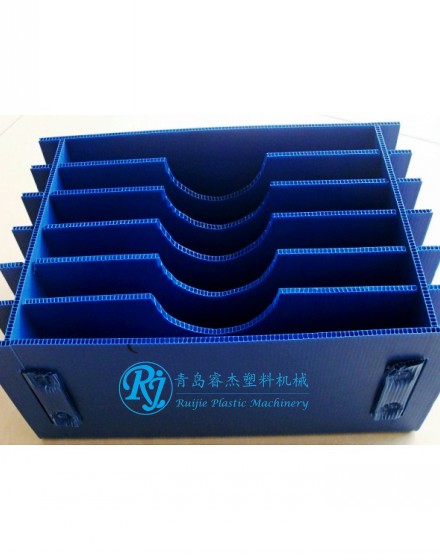

Widely used in architecture for light partitions, building material protection boards, and packaging for aquatic vegetable and fruit packaging boxes, turnover boxes, etc.

In addition, PP hollow sheet are colorful, printable, and processable that are also widely used in stationery, Card supplies, etc.

Contact

Contact