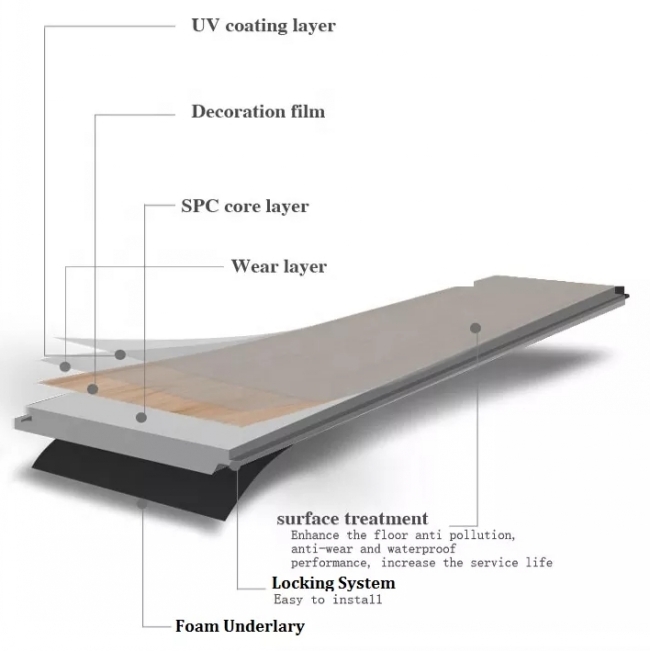

1. SPC floor structure: UV protection layer; Wear layer; Printed film; SPC core; Anti-slippery underlayment; Shock absorption underlayment.

2. SPC flooring density: 1.9-2.1g/cm³.

3. Dimentional stability: ≤ 0.15%(80℃,6H)

4. Main ingredients: PVC+CaCO3+Processing accessory ingredien

5. Equipments of spc flooring production line: extruder, mold, calender, oil temperature controller, traction machine, cutting machine, automatic stacker, roller conveyor.

SPC flooring Process Flow

mixer and dust-collection systems(mixing raw material)– extrusion line(semi-finished floor)–UV coating machine–slitting machine–Slotting machine–Flooring backside laminating line –packing machine–finished product(There is crusher and miller for recycled floor product.)

Machine Models

| No | Model number | SJSZ110/220 | SJSZ115/230 | SJSP136 |

| 1 | Double screw type | Conical | Conical | Parallel |

| 2 | Extruder motor | 185KW | 200KW | 160KW |

| 3 | Total power | 350KW | 380KW | 300KW |

| 4 | Rollers of Calender | Five rollers | Five rollers | Five rollers |

| 5 | Capacity | 1000-1300kg/h | 1600-1900kg/h | 1700-2100kg/h |

| 6 | ㎡/24h(4mm thick floor as example) | about 3000-3500 | about 4500-5500 | about 5000-6000 |

EIR (Embossing In Registered) wooden pattern effect

EIR wooden pattern film is pressed by EIR wooden pattern roller,The patterns on the color film coincide with the wood grain of roller to achieve a more realistic solid wood effect.

SPC floor has a wide selection of designs, suitable for indoor home improvement, hotels, hospitals, shopping malls and other public places.

Contact

Contact