PVC roof tile introduction

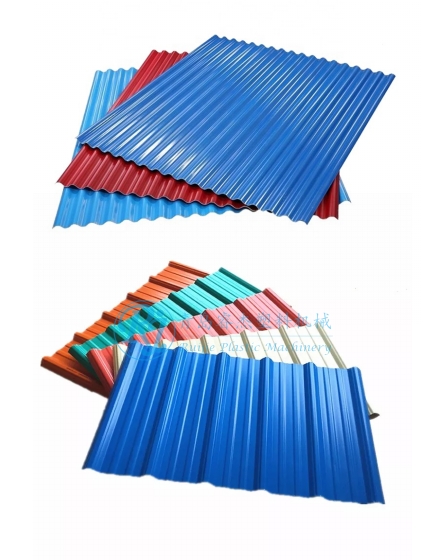

Product Type: PVC Roofing Sheet/tile

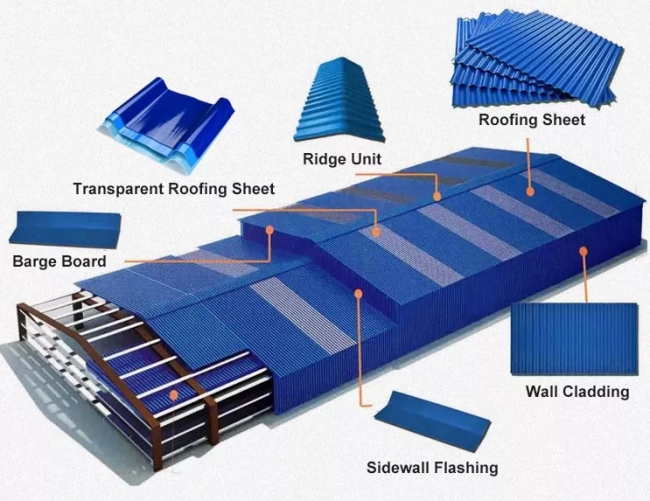

Shape: Corrugated 720, C930, C1100, C1130

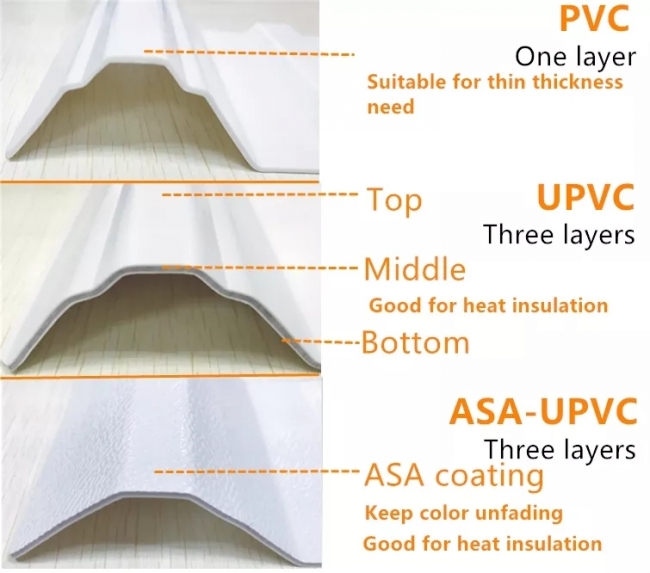

Surface: ASA coating PVC, UPVC type

Layer Type: Single Layer, 3 Layers, 4 Layers

Color: Green.White,Blue,Yellow,Grey etc.

Width: 720mm, 930mm, 1100mm, 1130mm

Available Width : 630mm, 840mm, 1008mm, 1040mm

Thickness: Generally 1.5mm-3.0mm

Advantages of the production line

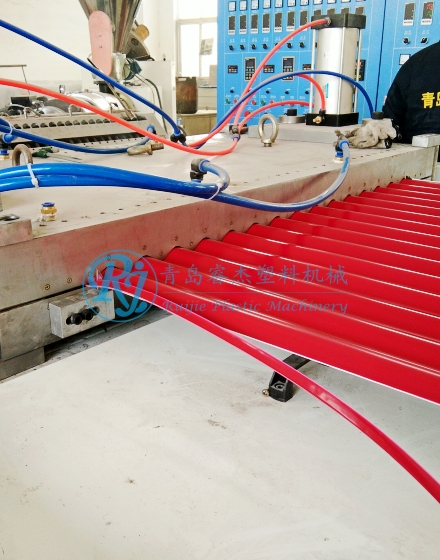

1. Equipped with coat hanger form flat die and a pneumatic shaping mould, this line has a more stable shaping process and more easily adjustable for the thickness control.

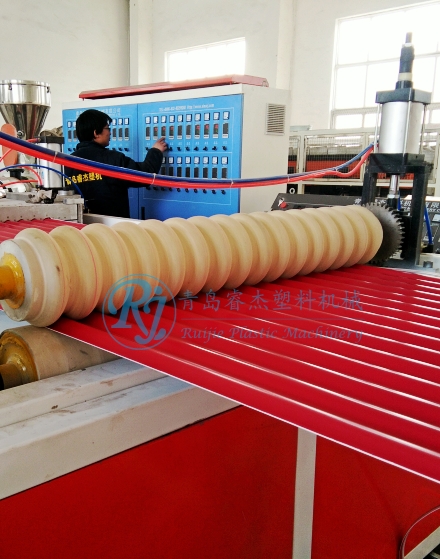

2. Using rubber hauling roller matched with the waveform of sheets, it provides more smooth traction.

3. Its automatic angular cutter ensures the cutting section tidy. It can be cut by metering length.

Equipment list

| Item | Machines list | Qty |

| 1 | Spiral Loader | 1 set |

| 2 | SJZ80/156 Conical double screw Extruder (SJSZ65/132 extruder for three or four layers) | 1 set |

| 3 | SJ50/30 Co extruder(For ASA layer or just laminate ASA film) | 1 set |

| 4 | Vacuum Loader+Hopper Dryer | 1 set |

| 5 | Mold/Die head set+Distributor | 1 set |

| 6 | Forming machine (with forming die,haul off, cutter and stacker) | 1 set |

Single layer or A+B/ A+B+C/ A+B+A layers available

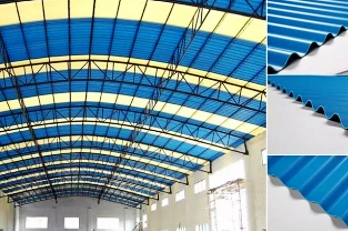

PVC roof tile is widely used in high-grade plant,steel plant, warehouse, farmer market and carport,etc.

Contact

Contact