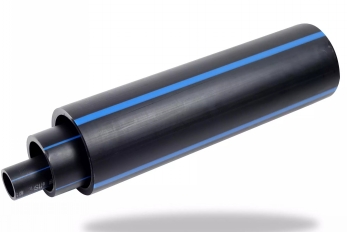

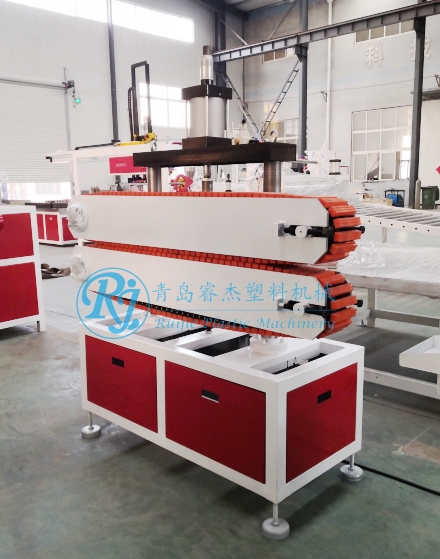

This machine is primarily used in the manufacturing of PE pipes/PPR pipes with diameters ranging from 20mm to 630mm. The various thickness of the pipes produced can make them suitable for applications range from urban water supply to gas transportation. This line also excels in the production of anti-flammable and anti-static electricity pipes using a two or three layer spiral mould for use in mining industries. Pipes produced feature even wall-thickness and perfect roundness. Through switching or adding certain part of machine unit, this line can also be customized to extrude pipes of various other kinds.

Process Flow

Raw material → Mixing → Vacuum Feeder →Plastic Hopper Drier→ Single Screw Extruder → Mould → Vacuum Calibration Tank → Spray Cooling Water Tank → Haul-off → No Dust Cutter →Stacker → Final Product Inspecting &Packing

Main Technical Parameters

| Item | Pipe diameter (mm) | Extruder | Motor power (kw) | Capacity (kg/h) | L/D |

| SJ63 | 20-63 | SJ65 | 37 | 80-150 | 33:1 |

| SJ110 | 20-110 | SJ65 | 55 | 100-200 | 33:1 |

| SJ160 | 50-160 | SJ75 | 75 | 150-250 | 33:1 |

| SJ250 | 50-250 | SJ75 | 110 | 400-500 | 33:1 |

| SJ315 | 110-315 | SJ90 | 160 | 280-400 | 33:1 |

| SJ450 | 200-450 | SJ90 | 160 | 600-800 | 38:1 |

| SJ630 | 315-630 | SJ120 | 250 | 800-1000 | 38:1 |

Contact

Contact