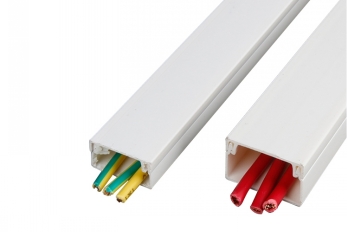

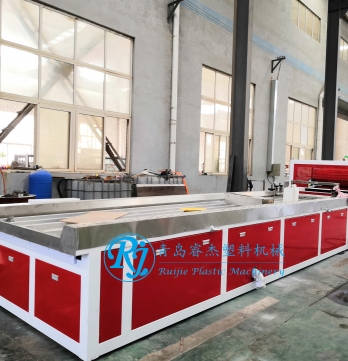

It is the ideal system for unobtrusive cable management designed to cope with the rigours of the factory and office. Include forced feeder, conical twin screw extruder, mould, vacuum calibration & cooling table, haul off machine, stacker, punching machine.

This machine can also produce PVC window and door profiles, panel and decorative profiles by changing mould.

Machine Features

1. High capacity

2.Long life

3.High speed extrusion

4.Low energy consumption

Process Flow

Raw material +additive → mixing → screw loader → conical twin-screw extruder → profile extrusion mould → vacuum calibration support → haul-off → cutter → rack →finished product

Models

| Model | SJZ51 | SJZ55 | SJZ65 |

| Max. width of products (mm) | 200 | 300 | 300 |

| Main extruder | SJZ51/105 | SJZ55/120 | SJZ65/132 |

| Extrusion capacity(kg/h) | 80-100 | 100-130 | 130-180 |

| Main motor power (kw) | 18.5 | 22 | 37 |

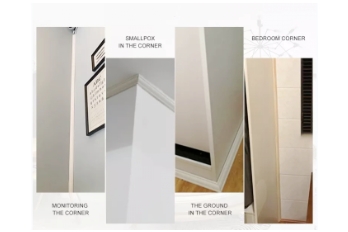

PVC cable trunking Application

Saddle design provide maximun stablility to wire bundles.Used in stage,electric, air conditioning or indoors.

Contact

Contact