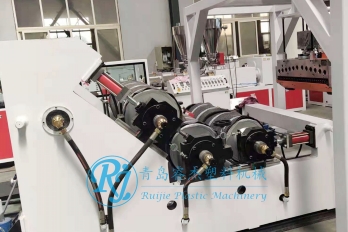

The whole machine adopts PLC control, automation of actual parameter setting, data operation, feedback, alarm and other functions.

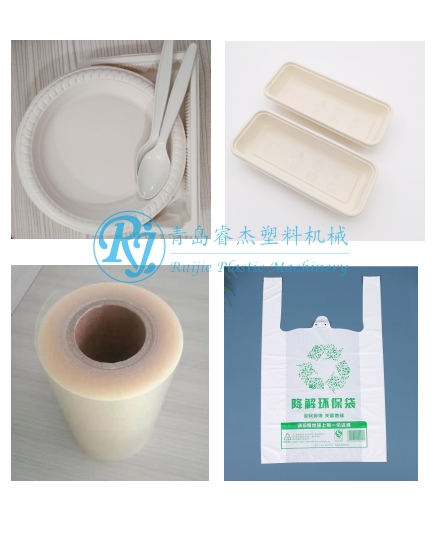

PLA Product Advantages

1. Starch — Natural raw materials: using natural corn starch as raw materials, it can be sustainably supplied, so that natural resources can be reused and recycled endlessly.

2. Degradation — Safe biodegradation: the raw materials are natural polymer compounds, which can be degraded in the natural environment.

3. Environmental protection — Green environmental protection: the products can be rapidly degraded by microorganisms in the natural environment after use, and become plant nutrients, truly from nature and also from nature, and effectively solve the environmental damage caused by white pollution.

4. Health — non-toxic: the raw materials are natural, the production process is sterile, the disinfection inspection is strict, the products will not be toxic to the soil and air after degradation, and there will be no secondary pollution.

5. International standard– fully in line with “4R+1D” international environmental protection standard (4R: Reduce, green material, recyclable, reciprocating production, 1D: degradation).

| Model | RJ –PLA 75 | RJ-PLA 85 |

| Extruder | 75 Parallel twin screw | 85 Parallel twin screw |

| Product Width | 800-1000mm | 800-1500mm |

| Output | 400-600KG/H | 500-800KG/H |

| Installed capacity | 290KW | 360KW |

PLA is widely used in hot forming, printing, metal packaging, etc.

Contact

Contact