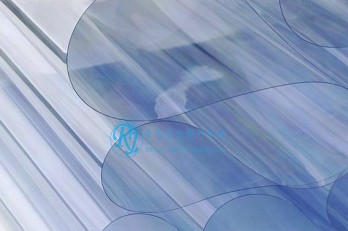

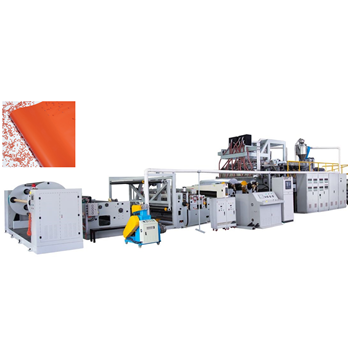

PETG high-gloss decorative film production line twin-screw exhaust production line (crystal-free drying): The newly launched crystal-free and drying-free exhaust type unit has the advantages of low energy consumption and high efficiency. Major technical upgrades have been made to the core vacuum system. The vacuum degree can be achieved, and the thin-walled roll set of alloy steel specially used for PETG is used to greatly improve the cooling efficiency, thereby increasing the output and improving the toughness and transparency of the product.

Multi-screw exhaust production line (crystal-free drying): The main machine used increases the area of material and air, and with the newly developed vacuum system, it can meet the needs of customers with large output and high quality sheets.

Equipped with a precision distributor, the layers are uniform, the proportion of each layer is adjustable, and the digital display is provided.

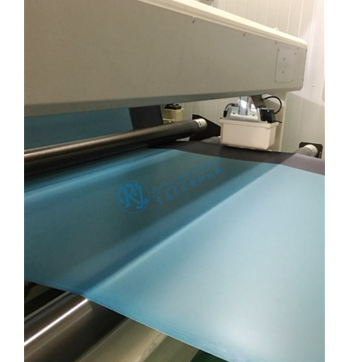

The inclined and horizontal tableting structure is more convenient for operation and maintenance.

The rollers are driven independently, the line speed and the extruder speed are synchronously closed-loop controlled, and the full servo system is used.

The whole machine is controlled by Siemens PLC, which realizes the automatic control of parameter setting, data operation, feedback, alarm and other functions.

| 1. Conditions of use:

① power supply |

380V/ 50Hz 3P+N+E |

| ②Cooling water | Temperature below 30℃, pressure 2-4Kg/cm2G, water flow 40m3/hr, water consumption 1.5m3/hr |

| ③Compressed air | Pressure 0.6-0.8Mpa, air consumption 1.5m3/hr |

| ④Installation place | Indoor (temperature 0°C—50°C, relative humidity 20%—80%) |

| 2. production material: | PET/PETG |

| 3. Extrusion output | 800Kg |

| 4. Product Specifications: | δ=0.15-1mm |

| 5. device color | Standard colors, color codes are available upon request |

Home appliance touch panel, decorative sheet, metal, glass, aluminum profile and other building surfaces, high-grade furniture surface high-gloss protection treatment

Contact

Contact