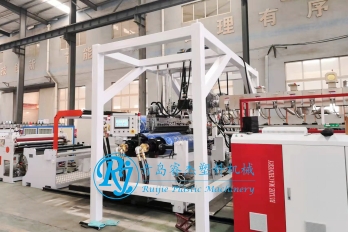

The whole machine has the advantages of uniform plasticization, stable extrusion, high output and long service life.

Production process: pet sheet is generally transparent color, other colors can be produced according to user requirements, just add color masterbatch.

| NO | Machine Name | QTY |

| 1 | Co-rotating Parallel twin screw extruder or Single screw extruder | 1 set |

| 2 | metering pump and screen changer | 1 set |

| 3 | Mould | 1 set |

| 4 | Three roller calender machine | 1 set |

| 5 | Temperature Control for calender | 1 set |

| 6 | Cooling bracket ,edge cutting device | 1 set |

| 7 | Dual surface coating and oven | 1 set |

| 8 | Haul-off machine | 1 set |

| 9 | Double station winder | 1 set |

| 10 | Electrical control part | 1 set |

| 11 | mixer (optional) | 1 set |

| 12 | Online crusher (optional) | 1 set |

| 13 | Crystallizer and dryer system (optional) | 1 set |

The PET sheets are mainly used to thermoforming machine or injection molding machine to produce packages box and containers for for food, milk, medicines, meat, cosmetics, etc.

Contact

Contact