PVC roof tiles are light, have good strength and are durable. PVC roof tiles are useful for decorative as well as heavy roofing applications. PVC roof tiles give high strength to weight ratio due to their low density.

Advantages of PVC Roof Tiles

1. Corrosion resistance

2. Sound absorption and heat insulation

3. Environment friendly and energy saving

4. Color lasting

5. Load bearing

6. Good water resistance

7. Light weight building materials

8. Fire proof grade B1

9. Easy to install

Features of this machine

1. Adopt PLC control and simple operation.

2. Adopt Electric-magnetic heater which can save 40% -60% electric power for customer.

3. All Electric Part (breaker/motor/relay /Inverter and so on ) is Siemens/Schneider/Omron

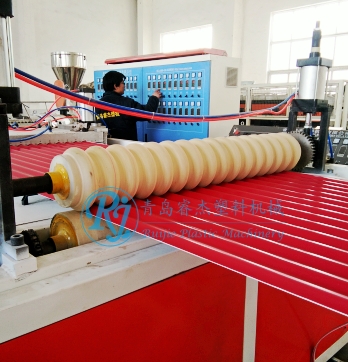

Working Flow

Raw materials →Conical twin screw extruder → Mould → Embossing machine→ Forming machine→ Cutting machine→ stacker

Equipment list

| Item | Machines list | Qty |

| 1 | Spiral Loader | 1 set |

| 2 | SJZ80/156 Conical double screw Extruder (SJSZ65/132 extruder for three or four layers) | 1 set |

| 3 | SJ50/30 Co extruder(For ASA layer or just laminate ASA film) | 1 set |

| 4 | Vacuum Loader+Hopper Dryer | 1 set |

| 5 | Mold/Die head set+Distributor | 1 set |

| 6 | Forming machine (with forming die,haul off, cutter and stacker) | 1 set |

Single layer or A+B/ A+B+C/ A+B+A layers available

PVC roof tile application

Wide range of application, workshop, warehouse, shed, farmers’ market, hoarding, wall body, temporary shops,etc.

Contact

Contact