The whole machine has the advantages of uniform plasticization, stable extrusion, high output and long service life.

This machine is one of the sheet production lines with mature technology and stable equipment performance in our company. It adopts three-roll calendering technology, mainly composed of extruder, hydraulic screen changer, mould, three-roll calender, Cooling traction bracket, double-station winding device and so on. The equipment is compact in structure and superior in performance. The screw and barrel are optimally designed.

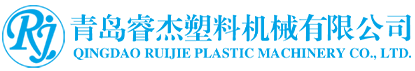

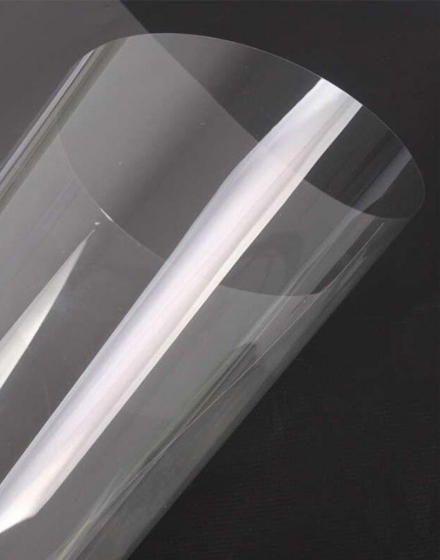

PET sheet is generally transparent color, other colors can be produced according to user requirements, just add color masterbatch.

Working Process

mixer(optional)–Co-rotating Parallel twin screw extruder or Single screw extruder–metering pump and screen changer–mould–Three roller calender–Temperature Control — Cooling bracket–Dual surface coating and oven(optional)–Haul-off machine–Double station winder

| NO | Machine Name | QTY |

| 1 | Co-rotating Parallel twin screw extruder or Single screw extruder | 1 set |

| 2 | metering pump and screen changer | 1 set |

| 3 | Mould | 1 set |

| 4 | Three roller calender machine | 1 set |

| 5 | Temperature Control for calender | 1 set |

| 6 | Cooling bracket ,edge cutting device | 1 set |

| 7 | Dual surface coating and oven | 1 set |

| 8 | Haul-off machine | 1 set |

| 9 | Double station winder | 1 set |

| 10 | Electrical control part | 1 set |

| 11 | mixer (optional) | 1 set |

| 12 | Online crusher (optional) | 1 set |

| 13 | Crystallizer and dryer system (optional) | 1 set |

The PET sheets are mainly used to thermoforming machine or injection molding machine to produce packages box and containers for for food, milk, medicines, meat, cosmetics, etc.

PET Film used to lamination on board,decorative effect.

Contact

Contact