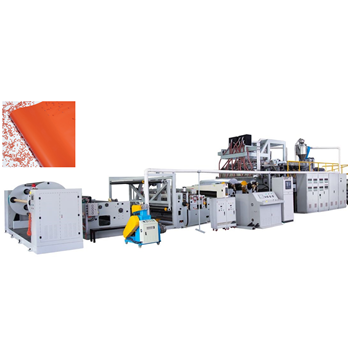

Features of the company’s cpp film equipment:

The cpp film production equipment developed by our company has a compact structure and excellent performance. The screw and barrel are optimally designed, and the whole machine has the advantages of uniform plasticization, stable extrusion, high output and long life.

Equipment composition of Cpp cast film production line:

The manufacturing technology of Cpp cast film production line, including the design of feeding, extruder, melt line (including filtration, metering), die, casting, drawing and winding, etc.

Features of the company’s cpp cast film equipment:

Thickness: 18-80um

Product structure: A/B/C,

Product layer ratio: 15-20/60-70/15-20

Die width: 3500mm

Width: 3200mm (after trimming)

Rewinding diameter (maximum): Ф1000mm (mechanical design limit)

Maximum mechanical line speed: 280m/min

Extrusion capacity: main extrusion: maximum 700kg/h auxiliary extrusion: maximum 300kg/h

What is cpp film?

CPP film is cast polypropylene film, also known as unstretched polypropylene film, which can be divided into general CPP (General CPP, referred to as GCPP) film, aluminized grade CPP (Metalize CPP, referred to as MCPP) film and Retort CPP (Retort CPP, RCPP for short) film, etc.

CPP is a polypropylene (PP) film produced by a cast extrusion process in the plastics industry. This type of film is different from BOPP (bidirectional polypropylene) film and is a non-oriented film. Strictly speaking, CPP films only have some orientation in the machine direction (MD) direction, mainly due to the nature of the process. Excellent clarity and finish on the film by rapid cooling on chill rolls.

CPP film is printed and bagged, suitable for:

(Composite film) Garment, knitwear and floral packaging bags; document and photo album films; food packaging.

(aluminized film) Metallized film for barrier packaging and decoration. After vacuum aluminum plating, it can be combined with BOPP, BOPA and other substrates to be used for high-grade packaging of tea, fried crispy food, biscuits, etc.

(Retort film) CPP is excellent in heat resistance. Since the softening point of PP is about 140°C, this type of film can be used in hot filling, retort pouches, aseptic packaging and other fields. In addition, it has excellent acid resistance, alkali resistance and grease resistance, making it the preferred material in the fields of bread product packaging or laminate materials. It is safe in contact with food, has excellent demonstration performance, does not affect the flavor of the food inside, and can choose different grades of resin to obtain the required characteristics.

(Functional film, also called special film) Potential uses also include: food outer packaging, candy outer packaging (twisted conjunctival film), medicine packaging (infusion bag), replacing PVC in the fields of photo albums, folders and documents, synthetic paper, non-drying Tape, business card holders, ring folders, and stand-up bag composites.

New application markets for CPP, such as DVD and video box packaging, bakery and pastry packaging, anti-fog films for vegetables and fruits, and flower packaging, as well as synthetic paper for labels.

Contact

Contact